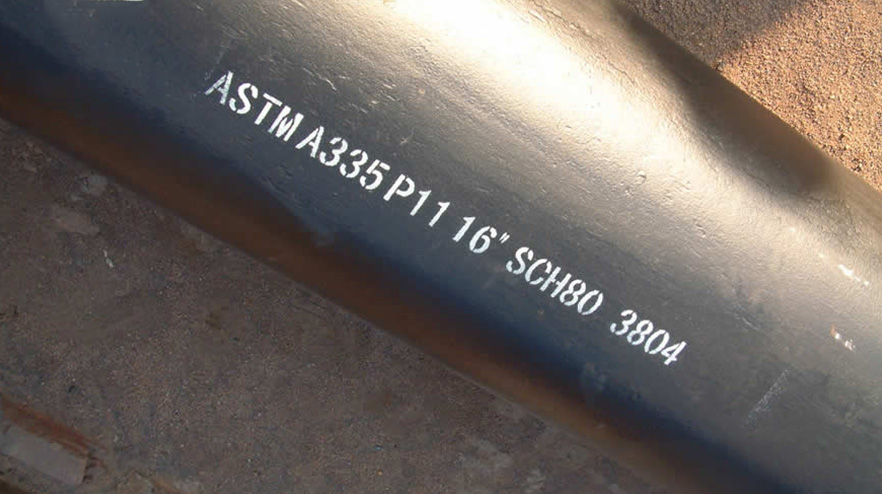

ASTM A335 P11 Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service.

The steel material shall conform to chemical composition, tensile property, and hardness requirements. Each length of pipe shall be subjected to the hydrostatic test. Also, each pipe shall be examined by a non-destructive examination method in accordance to the required practices.

The different mechanical test requirements for pipes, namely, transverse or longitudinal tension test, flattening test, and hardness or bend test are presented.

Both ends of each crate will indicate the order no., heat no., dimensions, weight and bundles or as requested.

Packing:

Bare packing/bundle packing/crate packing/wooden protection at the both sides of tubes and suitably protected for sea-worthily delivery or as requested.

Inspection and Test:

Chemical Composition Inspection, Mechanical Properties Test(Tensile Strength,Yield Strength, Elongation, Flaring, Flattening, Bending, Hardness, Impact Test), Surface and Dimension Test,No-destructive Test, Hydrostatic Test.

Surface treatment:

Oil-dip, Varnish, Passivation, Phosphating, Shot Blasting.

Both ends of each crate will indicate the order no., heat no., dimensions, weight and bundles or as requested.

ASTM A335 P11 Chemical Compositions(%)

Compositions Data

UNS Designa-tion K11597

Carbon 0.05-0.60

Manganese 0.30-0.60

Phosphorus(max.) 0.025

Sulfur(max.) 0.025

Silicon 0.50-1.00

Nickel …

Chromium 1.00-1.50

Molybdenum 0.44-0.65

Other Elements …

Mechanical Properties for ASTM A335 P11

Properties Data

Tensile strength, min, (MPa) 415 Mpa

Yield strength, min, (MPa) 205 Mpa

Elongation, min, (%), L/T 30/20

Material & Manufacture

Pipe may be either hot finished or cold drawn with the finishing heat treatment noted below.

Heat Treatment

– A / N+T

– N+T / Q+T

– N+T

Mechanical Tests Specified

– Transverse or Longitudinal Tension Test and Flattening Test, Hardness Test, or Bend Test

– For material heat treated in a batch-type furnace, tests shall be made on 5% of the pipe from each treated lot. For small lots, at least one pipe shall be tested.

– For material heat treated by the continuous process, tests shall be made on a sufficient number of pipe to constitute 5% of the lot, but in no case less than 2 pipe.