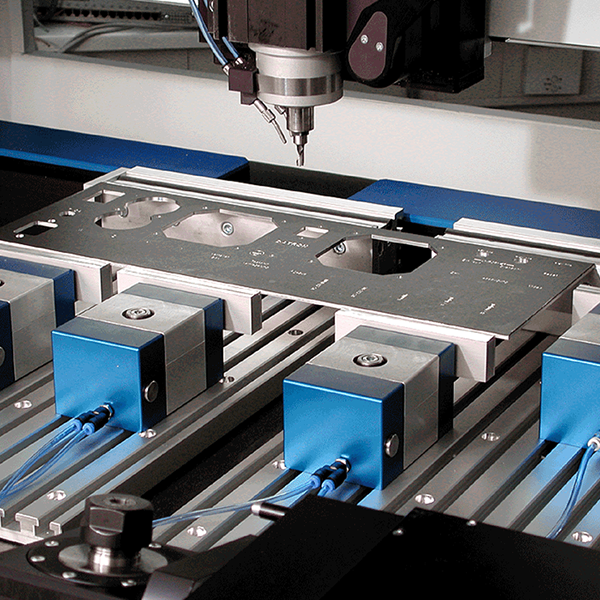

Total Guide to CNC Jigs, Fixtures, and WorkholdingSolutions for Mills. Workholding is the generic term for any device used to firmly hold your workpiece while machining it. A fixture holds your workpiece while it is being cut.

NC workholding, fixturing, work handling … most CNC manufacturers just don’t get involved in workholding. They sell you their machine and let you find a way to hold your parts once it arrives.

Workholding is the generic term for any device used to firmly hold your workpiece while machining it.

Closely related terms are “jigs” and “fixtures.”

A fixture holds your workpiece while it is being cut. A jig holds the workpiece and also guides the cutter. Given CNC, there’s little need for jigs as the g-code guides the cutter, so the term is largely related to manual machining.

“Fixtures” are colloquially workholding solutions that are custom made for a particular part or situation.

There are two components to workholding:

– The actual workholding device, such as a milling vise.

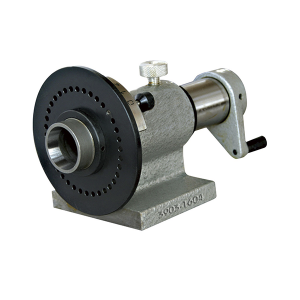

– The method of locating and securing that workholding device to your machine. This includes the ubiquitous T-Slots but goes on to include modular fixture plates, 4th axis solutions, and much more.

We’ll go through the various methods of locating the workholding devices and then follow up with a description of your choices for workholding devices.

But first, let’s talk about why Jigs and Fixtures are important and how to know when you need to make a special jig or fixture.