Corrugated and grooved gaskets. Corrugated and grooved gaskets are part of the semi-metallic category. This type of gasket is a mixture of metal and a sealing material that plays the role of an elastic element between the two sealing surfaces.

The most common types of gaskets are:

Gaskets used in piping (flange gaskets)

Gaskets used in vehicles (cars, boats, planes, trains)

Gaskets with certain material properties (cork, rubber paper etc.)

Gaskets used for a particular function (for pressure, temperature, or chemical resistance)

Bespoke or custom made gaskets.

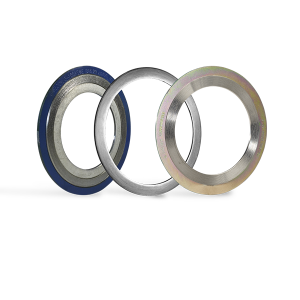

Corrugated and grooved gaskets are part of the semi-metallic category. This type of gasket is a mixture of metal and a sealing material that plays the role of an elastic element between the two sealing surfaces. Corrugated and grooved gaskets are used for the sealing of flange joints from heat exchangers, under-pressure recipients, valves, high pressure pumps in petrol-chemistry, oil refining, paper, energy and nuclear industries.

The most often used gasket is the grooved gasket (kammprofile), followed by the corrugated and jacketed gaskets.

Advantages of grooved gaskets:

Depending on the metal core, the gaskets can be refurbished (the only type of gaskets that can be used again after having been refurbished)

Very good sealing properties for a wide variety of seating stress levels

Helps the compensating of high temperatures and pressure fluctuations

Excellent when used for narrow flanges

Easy to manoeuver

Main standards for grooved gaskets:

ASME B16.20

EN 1514-6

EN 12560-6

Recommended thickness of the ring: 3 mm or 4 mm.

Recommended thickness of the sealing material: 2 x 0.5 mm or 2 x 1 mm.

Standard materials:

Metallic ring: SS 304; SS 316L; SS 321; SS 304L; Carbon steel

Sealing material: flexible graphite; PTFE; Mica; Ceramics

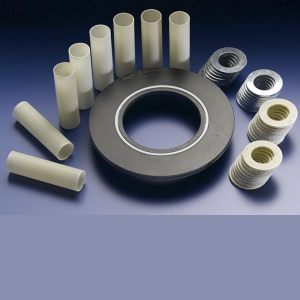

Corrugated gaskets

are manufactured from a core of profiled metal plate in order to ensure the rigidity and durability of the gasket.

The shape of the profile and the thickness of the gasket depend on the diameter and width of the gasket.

Graphite layers can totally cover the metallic profile or, by request, just the inside part so that the gasket could also have a centre ring.

Working parameters:

Are strictly connected to the materials that are to be used in the manufacturing of spiral wound gaskets.

Temperatures: -200°C… 550°C

Pressure: max 160 bar

pH: 0…14

Recommended thickness of the core: 0,5 mm.

Recommended thickness of the sealing material: 2 x 1 mm.

Advantages of corrugated gaskets:

Very good sealing properties at low seating stress levels

Excellent resistance to radial shear

Resistance to thermal cycling

Can be used for flanges with imperfections

Standard material:

Metal material: SS 304; SS 316L; SS 321; SS 304L; Carbon steel

Sealing material: Flexible material; PTFE; Mica; Ceramics